| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

TR4/TR5

STEELMAMA

RS1

8.5KW

15M/MIN

100 SQURE METERS

2

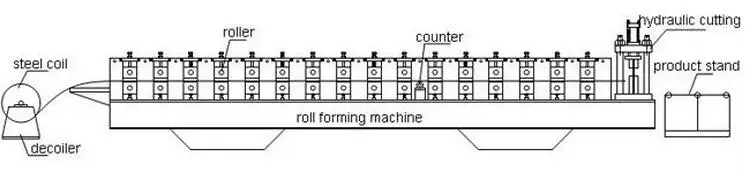

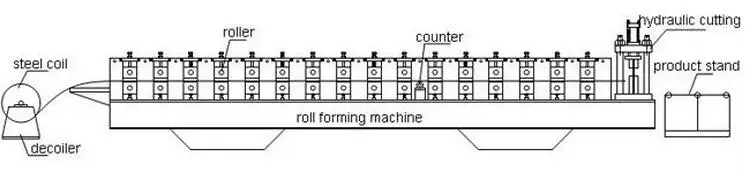

Working Flow:

Supply components of the machine:

| Description | Quantity (set) |

| 6Tmanual decoiler | 1 |

| Guiding device | 1 |

| Hydraulic pre cutter | 1 |

| Forming system | 1 |

| Transmission system | 1 |

| Hydraulic guillotine&punching | 1 |

| Support table | 2 |

| Hydraulic station | 1 |

| Control box | 1 |

| Spare parts and tools | 1 |

2.3. General Parameters of machine:

| NO | ITEM | Parameter |

| 1 | Forming Speed | Max18m/min(depend on quantity of punching) 10-15METERS/MIN depends on the quantity of punching holes |

| 2 | Forming station | Around 18 groups |

| 3 | Total Power | About 5.5 KW |

| 4 | Total Weight | About 6500kgs |

| 5 | Voltage | 220v,50hz,3p |

| 6 | Diameter of shaft | 70/80mm |

| 7 | Installation Size | 9.5 * 1.2 M*1.5 |

| No | Item | Parameter |

| 1 | Forming Shaft | s45c with grinding process and heat treatment HRC28-32,twice CNC |

| 2 | Forming Roller | s45c with vacuum heat treatment with hard chrome coatingHRC50-52 |

| 3 | Cutting Blade | Cr12MoV with hard treatment |

| 4 | Control System | PANASONIC PLC, others are Schneider etc. |

| 5 | Electrical motor | China quality brand |

| 6 | Touch screen | Win view |

| 7 | PLC | Panasonic |

| 8 | Rely | Schneider |

| 9 | Encoder | Omron |

Working Flow:

Supply components of the machine:

| Description | Quantity (set) |

| 6Tmanual decoiler | 1 |

| Guiding device | 1 |

| Hydraulic pre cutter | 1 |

| Forming system | 1 |

| Transmission system | 1 |

| Hydraulic guillotine&punching | 1 |

| Support table | 2 |

| Hydraulic station | 1 |

| Control box | 1 |

| Spare parts and tools | 1 |

2.3. General Parameters of machine:

| NO | ITEM | Parameter |

| 1 | Forming Speed | Max18m/min(depend on quantity of punching) 10-15METERS/MIN depends on the quantity of punching holes |

| 2 | Forming station | Around 18 groups |

| 3 | Total Power | About 5.5 KW |

| 4 | Total Weight | About 6500kgs |

| 5 | Voltage | 220v,50hz,3p |

| 6 | Diameter of shaft | 70/80mm |

| 7 | Installation Size | 9.5 * 1.2 M*1.5 |

| No | Item | Parameter |

| 1 | Forming Shaft | s45c with grinding process and heat treatment HRC28-32,twice CNC |

| 2 | Forming Roller | s45c with vacuum heat treatment with hard chrome coatingHRC50-52 |

| 3 | Cutting Blade | Cr12MoV with hard treatment |

| 4 | Control System | PANASONIC PLC, others are Schneider etc. |

| 5 | Electrical motor | China quality brand |

| 6 | Touch screen | Win view |

| 7 | PLC | Panasonic |

| 8 | Rely | Schneider |

| 9 | Encoder | Omron |