| Availability: | |

|---|---|

| Quantity: | |

| PDF Export | |

Customized welding pipe machine with punching

Customized Full Automatic Profile Special Design Metal Welding Pipe Cold Roll Forming Machine With Punching

PRODUCT DISPALY

Customized welding pipe machine with punching

Customized welding pipe machine

Pipe Tube Machine

Meta welding pipe machine

welding pipe machine factory

Metal Customized Wwelding Pipe Cold Roll Forming Machine

Customized welding pipe machine factory

What is pipe elbow machine used for?

Elbow machines are used to produce various types of elbows used in HVAC, drainage systems, process industry piping, ventilation, heating and cooling systems, and many other applications of the construction industry. Most elbows are made of copper, aluminum or stainless steel pipes.

Machine Flow ChartPipe Elbow Machine Supplier

Uncoilerj → Molding core → Hydraulic System → Automatic Control system → Step Formed

Mechanism → Automatic Shearing Mechanism → Products Receiving Tables

Roll Forming Machine Components:

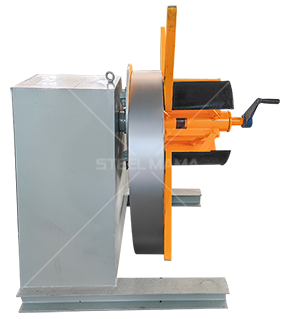

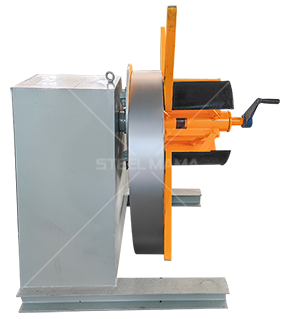

Decoiler

1 set Feeding Device

1 set Forming Machine

1 set Cutting Device

1 set PLC Control Box

1 set Hydraulic Pump Station 1 set

1 Decoiler

Max. Width 300mm

Inner Diameter Φ450 – Φ550 mm Out Diameter 1500 mm Max. Loading Capacity: 1500 kgs Working Way Passive or hydraulic

2 Feeding device

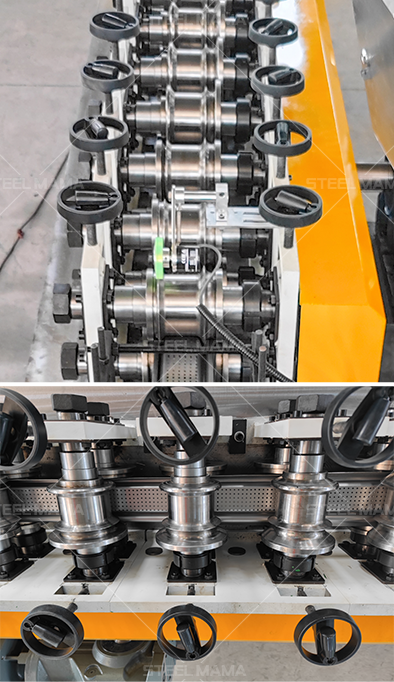

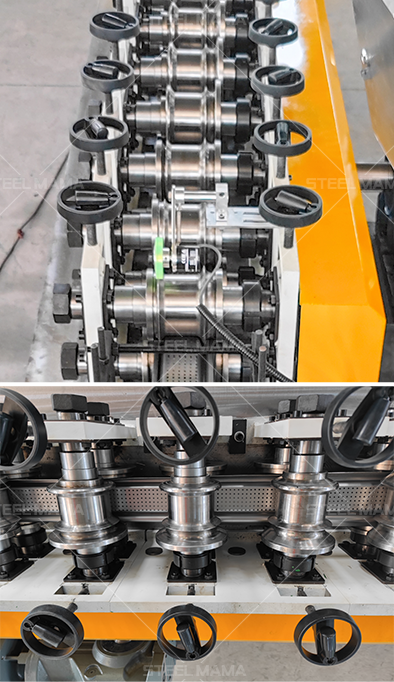

3 Roll Forming Machine

Material Thickness 0.6-1.2mm PPGI and GI

NO. of Roller Stations 14 stations Material for Rollers CR12# steel polished and coated

with chrome HRC58-62°

Material for Shaft High grade 45# steel polished(CNC lathe) Diameter of Shaft 50mm(Solid shaft) Frame Panel 25mm Bottom Frame 12mm steel plate welding Motor Power 5.5 KW(shanghai motor) Driven Type Gear Drive Speed About 8-15m/min 4 Cut-off Device

Material for Cut-Off Modular Cr12 steel after treatment Hardness for Heat Treatment HRC58 – 62° Cut-Off Type Qualified pillar cutting Motor for Hydraulic Stand 5.5KW Punching Die Material Cr12 steel after treatment

5 PLC Control Box

Type PLC Frequency Control System with touch screen

PLC Brand Delta Encoder Brand: Omron Length Error ±2mm Language English and Chinese Voltage 380v/50HZ, 3Phase (It depends on customer requirement)

6 Hydraulic Pump Station

Oil type 46# hydraulic oil

Pump brand China brand Motor power 4kw Solenoid valves Huade brand Solid valve Single Cooling way Fan

Related Plate Type

Glazed Tile Type Roll Forming Sheet

Corrugated Type Roll Forming Sheet

IBR Type Roll Forming Sheet

Factory Show:

1234 STEELMAMA was founded in 2009. Since its inception, STEELMAMA has always uphold the "create a first-class enterprise, first-class talents, first class contribution" vision, to create a well-known "STEELMAMA" brand. STEELMAMA’s main business is to "project" as the theme of “CHINA STEEL AGENT SERVICE”, leading products for steel profilemachinery include roll forming machine, press brake bending machine and other steel processing machinery, and steel coil include PPGI coil, GI coil, Aluminium coil, Alu-zinc coil and steel strips and plates, also steel building material like metal roofing sheet, purlin sections, H steel, welding mill tube and some hardwares to be global brand.

123

FAQ

1234 1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can produce more than 6 kinds of panels.2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

3. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

4. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

6. You are trade company or factory?

We are trade company but we also have own factories. Building trade company is just for exporting various types of cold roll forming machines. 7. Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing How to make machines much more automatic, accurate and high quality. We can make sure thatour machine could use more than 20 years without any problem. We can provide 2 years free qualityassurance.

8. How long the machine could be made?

Normally speaking, welded pipe making machine could be made without 45 working days. If you need machines in a hurry, we can make it for you less than a month.

1234

Customized Full Automatic Profile Special Design Metal Welding Pipe Cold Roll Forming Machine With Punching

PRODUCT DISPALY

Customized welding pipe machine with punching

Customized welding pipe machine

Pipe Tube Machine

Meta welding pipe machine

welding pipe machine factory

Metal Customized Wwelding Pipe Cold Roll Forming Machine

Customized welding pipe machine factory

What is pipe elbow machine used for?

Elbow machines are used to produce various types of elbows used in HVAC, drainage systems, process industry piping, ventilation, heating and cooling systems, and many other applications of the construction industry. Most elbows are made of copper, aluminum or stainless steel pipes.

Machine Flow ChartPipe Elbow Machine Supplier

Uncoilerj → Molding core → Hydraulic System → Automatic Control system → Step Formed

Mechanism → Automatic Shearing Mechanism → Products Receiving Tables

Roll Forming Machine Components:

Decoiler

1 set Feeding Device

1 set Forming Machine

1 set Cutting Device

1 set PLC Control Box

1 set Hydraulic Pump Station 1 set

1 Decoiler

Max. Width 300mm

Inner Diameter Φ450 – Φ550 mm Out Diameter 1500 mm Max. Loading Capacity: 1500 kgs Working Way Passive or hydraulic

2 Feeding device

3 Roll Forming Machine

Material Thickness 0.6-1.2mm PPGI and GI

NO. of Roller Stations 14 stations Material for Rollers CR12# steel polished and coated

with chrome HRC58-62°

Material for Shaft High grade 45# steel polished(CNC lathe) Diameter of Shaft 50mm(Solid shaft) Frame Panel 25mm Bottom Frame 12mm steel plate welding Motor Power 5.5 KW(shanghai motor) Driven Type Gear Drive Speed About 8-15m/min 4 Cut-off Device

Material for Cut-Off Modular Cr12 steel after treatment Hardness for Heat Treatment HRC58 – 62° Cut-Off Type Qualified pillar cutting Motor for Hydraulic Stand 5.5KW Punching Die Material Cr12 steel after treatment

5 PLC Control Box

Type PLC Frequency Control System with touch screen

PLC Brand Delta Encoder Brand: Omron Length Error ±2mm Language English and Chinese Voltage 380v/50HZ, 3Phase (It depends on customer requirement)

6 Hydraulic Pump Station

Oil type 46# hydraulic oil

Pump brand China brand Motor power 4kw Solenoid valves Huade brand Solid valve Single Cooling way Fan

Related Plate Type

Glazed Tile Type Roll Forming Sheet

Corrugated Type Roll Forming Sheet

IBR Type Roll Forming Sheet

Factory Show:

1234 STEELMAMA was founded in 2009. Since its inception, STEELMAMA has always uphold the "create a first-class enterprise, first-class talents, first class contribution" vision, to create a well-known "STEELMAMA" brand. STEELMAMA’s main business is to "project" as the theme of “CHINA STEEL AGENT SERVICE”, leading products for steel profilemachinery include roll forming machine, press brake bending machine and other steel processing machinery, and steel coil include PPGI coil, GI coil, Aluminium coil, Alu-zinc coil and steel strips and plates, also steel building material like metal roofing sheet, purlin sections, H steel, welding mill tube and some hardwares to be global brand.

123

FAQ

1234 1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can produce more than 6 kinds of panels.2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

3. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

4. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

6. You are trade company or factory?

We are trade company but we also have own factories. Building trade company is just for exporting various types of cold roll forming machines. 7. Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing How to make machines much more automatic, accurate and high quality. We can make sure thatour machine could use more than 20 years without any problem. We can provide 2 years free qualityassurance.

8. How long the machine could be made?

Normally speaking, welded pipe making machine could be made without 45 working days. If you need machines in a hurry, we can make it for you less than a month.

1234