Views: 2171 Author: STEELMAMA Publish Time: 2022-08-01 Origin: Cold roll forming machine

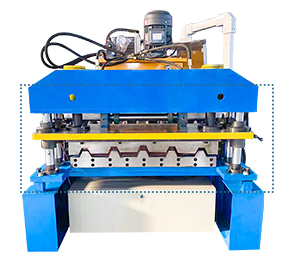

Roll Forming Machine Components:

Roll forming is a metal fabrication process that involves the bending of metal strips to create a certain shape or design. It's one of the most simple and easy-to-understand metal forming processes there is; however, there are several components that go along with it.

These machines also can perform several other metalworking duties, such as material cutting and roll punching.The majority of roll-forming machines work in a continuous cycle. This means the metal coil will be fed into one end of the device and will be passed through each of the machine's components continuously until the final product exits at the end.Roll forming machines have several stations where rollers are used to create the bends in the metal according to the specifications, each set of rollers bending the metal further to complete the required shape in a progressive cycle.

Roll forming machines are highly efficient, operating at speeds between 30 to 600 feet per minute. This makes them essential for businesses that require huge numbers of the same metal precise products to be manufactured over time.

Once you learn about these components and the role they play in the metal fabrication process, you'll understand exactly how your roll formed part is made.

All roll forming machines have the same essential design components. These include:

1-De Coiler

This is where the metal coil can be loaded and will be uncoiled according to the pre-programmed speed.

Strip accumulator and slack loop - this component allows the coil strip to pause, allowing for a pre-punch press stroke without disrupting the roll form mill.

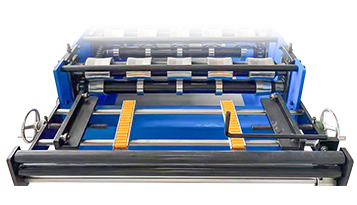

2-Feeding roller and leveling

Where the metal is straightened and leveled out in preparation for manipulation.

3-Pre-punching and marking

In some designs, holes are required before the metals bent into its final shape.

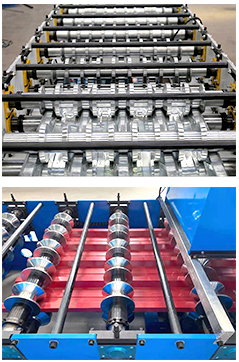

4-Forming stations/ the roll die mill

This is where the material is progressively passed through various sets of rollers, each set manipulating the metal a little more. Once this has taken place, the part is then passed through several straightening dies and side rollers to ensure complete accuracy. This process will eliminate any twist, bow, or camber of the metal, which could end up distorting the final shape. This component in the process can also be referred to as torque head or final guide.

Roll Forming Machine Rollers

Rollers is one the main core of roll forming machine compoents. In practical terms, rollers manufacturing must be extremely precise. The deviations of roundness or eccentricities of a very low order will have great implications in part quality. And the surface quality must be extremely high due to contact and lubrication issues. As usual rollers are split into several sections for ease of manufacturing. In fact, there are instances where this is the only possibility and also allows for easier installation.

Between the rollers are spacers, which will reduce the cost of the mill. And easy to adjust to produce different desired profile with splited spacers.

Shafts/Axis

The shafts is for supporting rolls and connecting them to the roll forming stands, must be very stiff in order to ensure good dimensional stability of the roll gap. The outer diameter of the shafts is from 40 mm to 120mm for different profiles. The shaft will have a keyway through its whole length which will fit with the rolls. The shaft jointed on bearings on both side stands.

On the drive side it will have a section with a larger diameter which rests on the bearing. On the operator side, it is threaded and has a spacer which fits into the bearing and allows the operator to tighten the whole assembly (rolls and spacers) with the nut, independently of the stand and bearings. The threads are usually opposite, the top one is right thread while the bottom one is left thread in order to avoid the unintentional untightening of the nuts during operation. On the drive side, the shaft has a standard shaft end for fitting a flange, cogwheel or chain drive.

Roll Forming Stands

Each side roll forming stand consists of two bearing housings, which are supported by connecting rods, in turn attached to cross bars. Each bearing housing usually has two conical bearings which support the shaft. The height of each shaft is adjusted by screws on the top and bottom crossbars. In order to change the rollers on a roll forming machine, the operator side stand must be removed. This means that positioning on the machine table must be precise and repalceable . If the stands are not correctly mounted, there is the possibility that the shafts are not perpendicular to the direction of travel, which can lead to substantial problems during operation.

There are Several driving methods for connecting the electric motor to the shafts. Chain drives are usual. But universal joint drive shaft which is for connecting the two parts. And which allows for

the independent driving of each roll, which can be useful due to the varying sheet speed through the roll forming machine.

5-Cutting and discharge

The cutting system - a hydraulic or mechanic saw will cut the metal to its precise length without disrupting the flow of the process. The resulting part will then be discharged onto the run-out table, ready for storage or shipment.

6-PLC Control Box

The purlin production line entirely has a top-notch electronic control system. The electrical control components of the purlin roll machine meet international specifications, and you can also specify your desired parts. The component

requirements include a transparent line number, clear markings, and reasonable parts.

7-Hydraulic Pump Station

Developments in roll forming machines

Many modern roll forming machines boast Computer-Aided Design (CAD) systems. These provide roll-forming machines with the ability to ensure complete accuracy, tighten tolerance levels, and catch any product imperfections early, thus reducing waste and maximizing business profits.

Quality, reliable roll forming machines from Roll Forming LLC

If you are looking for a roll forming machine for your business, browse the range from STEELMAMA . We are proud suppliers of top-quality roll forming machines, and our passionate team of experts is on hand to help ensure you choose a suitable machine for your business, so get in touch today.

View More information about roll forming machine line.

VIEW our Youtube More machine video

CONTACR US

Phone:+86 17761555057

Email:arno@steelmama.com